Soundwell DYNAMIC

Soundwell Electronic Products (Guangdong) Co., Ltd.

TEL:+86(769)-38833333-881

Fax:sw@soundwell-cn.com

MAIL:soundwell868@soundwell.cn

Address:Guangdong Province Dongguan city Tangxia Town Phoenix Gang Sheng Wei Industrial Park

How to wire the rotary encoder?

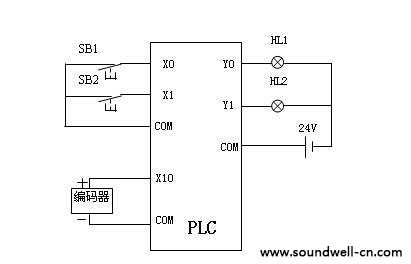

In incremental rotary encoder, for example, we usually use the incremental rotary encoder, incremental rotary encoder output pulse signal is directly input to the PLC, use PLC high-speed counter to count their pulse signal to obtain measurement results. Since the number of the rotary encoder output pulse is different, and some rotary encoder output A, B, Z phase pulse, and some only A, B two-phase, only the A phase easiest. Up to A, A +, A-, B, B +, B-, Z, Z +, Z- three sets of three-phase pulse.

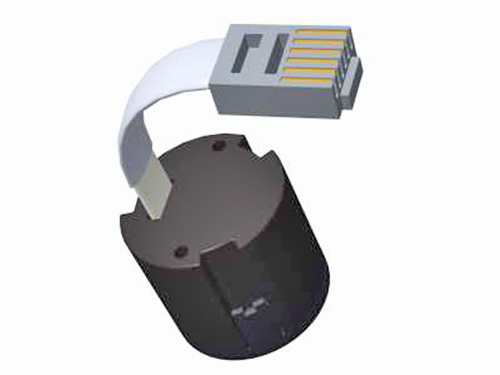

About a rotary encoder lead Common rotary encoder has five leads, where 3 is a pulse output line, a COM is the end line, a power cord (OC gate output type). Power source may be an external power supply, can also directly use the power of the PLC. Power "-" terminal to be connected with COM encoder "+" power supply terminal and encoder connections. COM of the encoder and the PLC COM input terminal is connected, A, B, Z two-phase pulse output is connected directly to the input of the PLC, A, B is 90 degrees pulses. There is a rotary encoder shielded cable, the use of shielded wire to the ground, improve immunity.

Understand the principle of rotary encoders and rotary encoders lead knowledge, following Guangdong Granville to share with electronic rotary encoders installation procedure, mainly four steps:

1. securely mounted encoders to avoid jarring loose

2. When the encoder connection, make sure that the load can not exceed the maximum allowable value

3. When the encoder wiring, make sure that there is no bias

4. Lock the coupling screws to avoid loosening during use

Prev: Increment type rotary encoder to use Next: Selection of parameters and rotary encoders rotary encoder Selection Considerations

.jpg)

.jpg)

.jpg)